How to Polish Aluminum at Home ?

Consider making a homemade aluminum enamel composed of inexpensive and easy-to-find ingredients.

Vinegar

A simple solution of vinegar and water will not only clean the aluminum surfaces, but will also polish the aluminum to restore its original shine. In a spray bottle, mix equal parts of water and white vinegar. Spray directly onto the surface and wipe with a soft cloth.

Cream of Tartar

It works to restore the brightness of aluminum while removing stains and dirt build-up. In a dish, mix two tablespoons of cream of tartar and slowly add water until a thick paste is formed. Rub directly onto the aluminum surface and polish using a fine-grained polishing pad. Wipe with a soft cloth to remove any residue.

Lemon juice and baking soda

A solution of lemon juice and baking soda may also be effective. In a dish, add two tablespoons of baking soda and slowly add the lemon juice until a thick paste forms. Rub the solution directly onto the aluminum surface with a soft cloth. Use a fine-grained polishing pad to remove any accumulated residue and polish the surface to its original shine.

How to Polish Scratched Aluminum ?

Toothpaste

- Household toothpaste contains aluminum dioxide, which is a very mild abrasive. Using a metal polisher, a polishing cloth and sandpaper.

- You will need a very fine sandpaper of about 1000 grains. You will use a technique known as wet sanding. This will not damage the aluminum, but will simply remove any small scratches it may have.

- Soak the sandpaper in water before use and carefully sand the areas of the piece that are scratched. Be sure to sand in small strokes.

- When you have finished sanding the surface with the sandpaper, the next step is to put some metallic polish on a soft cloth.

- Work the glaze into the scratched areas in a circular motion. Once you have finished, wash the piece well to remove any polish residue left.

- Finally, use a polishing cloth on the dry piece to increase the shine and give it a reflective finish.

How to Polish Anodized Aluminum ?

- Sand your aluminum surface with 800 grit sandpaper. Use a firm touch and continue sanding until the aluminum appears perfectly smooth.

- Hand wash it with or without a sanding block, or use a power sander if you know how to use one of these devices correctly.

- Place a polishing pad in a hand-polishing machine and turn it on. Slowly move the polishing pad in a circular motion across the entire aluminum surface, then wipe with a soft cloth.

- Apply commercial aluminum enamel or anodized aluminum enamel to the surface. This is your final polish.

- Squeeze a portion of the enamel on a soft cloth and rub it with circular movements on the surface.

How to Hand Polish Aluminum ?

Now, this process can be done with practically any metal, but aluminum is soft and does not oxidize.

STEP 1:

- Clean the piece you are working with. Cleaning it of grease or dirt everywhere.

STEP 2:

- Depending on the finish, you may be able to skip this step. If your part is not machined and still has the casting, or just has a very rough finish, you will probably want to follow this step.

- You will now use a right angle die grinder with a sanding wheel or very abrasive sandpaper (approximately 60 grits on the sandpaper, 120 or more on the grinder).

- Using the die grinder requires constant movement and close monitoring of what you are doing. It will easily tear the surface.

STEP 3:

- With 180-220 grit sandpaper (wet/dry), you will wet the part until you notice no deeper and wider than 60 grit marks.

- This will take some time, but this step will make the metal look scratched and “brushed”, but not as smooth as the image below.

STEP 4:

- Go from the previous 220, to 320, to 400, to 600, to 800, to 1000, to 1200, to 2000.

- Eventually, the piece will look and feel very smooth. With each step, it will remove the scratches from the previous step and replace them with finer scratches from the current grain.

STEP 5:

- wash the piece again. Make it as clean as possible for this step. Take the piece to a clean environment, use a NEW rag / t-shirt / towel (make sure it is soft) and apply the rag to the enamel.

- Wrap the cloth around your thumb or fingers and start moving it in a circular motion. It will turn black very quickly, but continue until it feels dry.

- At this point, it should have a little shine. Repeat this until it is polished.

How to Polish Aluminum for Motorcycles ?

- Aluminum is the perfect metal for use in motorcycle parts because of its strength and weight.

- Apply varnish stripper on a cloth and rub the varnish on the motorcycle parts; aluminum parts have a protective varnish that must be removed before polishing.

- Wash the parts with soap and water. Dry the parts with a towel.

- Sand all scratches with sandpaper until the metal surface is smooth. Use even strokes to sand the aluminum. Sand the metal until it is completely smooth.

- Apply aluminum enamel to the fabric and rub it on the metal with slow, circular movements. The fabric must become black when rubbing the enamel: it is the aluminum tarnish that comes off the pieces.

- Make sure that each part is well polished. Dry the metal with a towel, eliminating all the polishing residue.

How to Polish Aluminum Wheels ?

- Remove and remove anything that gets in the way. Valve stems. Wheel weights. Stickers All.

- Then clean things up. Use a strong degreaser, heavy-duty scouring pads and some elbow grease.

- Rinse the wheels well. You don’t want to polish any dirt on the aluminum.

- Use a flat file to soften any unpleasant rashes. Do not remove too much material or the wheel may be affected.

- Apply some of the thicker or more abrasive compound to the stiffer polishing wheel.

- Use the correct combination of rpm and pressure to make the compound work. Buff the entire wheel one section at a time.

- Clean the entire surface of the wheel between each step.

- Use a separate wheel for each compound to avoid contamination between steps. Here, a less abrasive compound is used with a “loosely stitched” wheel for a polished finish.

- The last step is a manually applied liquid hand polish and subsequent hand polish. Now, polish the other three wheels.

How to Polish Aluminum Engine

- Allow the aluminum engine to cool completely.

- Place a nozzle on a garden hose and turn it on. Thoroughly spray the aluminum engine fins with a strong jet of water. This will loosen and remove any surface film.

- Place the shampoo in a bucket and fill it with water from the garden hose to make a soapy mixture.

- Soak a sponge in the shampoo mixture and scrub the engine well. Press the sponge on the sides of each flap to reach deep inside and clean it.

- Spray the engine with a strong force from the garden hose.

- Allow the engine to dry.

- Place a small polishing wheel on the chuck of a drill.

- Add a stream of aluminum polish to the cone shaped tip of the wheel.

- Turn the drill to the “On” position and insert the wheel tip into the side of each flange to reach the deepest area of the motor. Pass the drill forward and backward along the side of each fin.

- Add additional polish to the tip as needed to polish the entire engine. Rinse the engine to remove any excess polish with the garden hose at full strength.

- Fold a chamois in half and hold each end with one hand to show. Press the chamois into the channel on one side of a flap and pass it through to dry.

- Continue this process on each side of each fin and all around the engine to dry it. Drain the chamois when it no longer absorbs water from the engine.

How to polish the Aluminium to Make it Chrome ?

This procedure is usually done on motorcycles, so we will explain it.

Step 1

Remove all parts of the bike that you intend to chrome finish, such as road studs, sidebars, exhaust pipes and wheel covers.

Step 2

- Place the metal parts and wash them with clean water and a towel to remove dirt or dust.

- You need many towels since you do not want to use a towel that has been used to remove dirt or sandpaper on a clean part.

- Don’t worry about drying the parts, this is a wet process.

Step 3

- Pour a few touches of car soap on your 220 grit sandpaper and immerse it in a container of water. Give your aluminum parts a full rub.

- Keep the sandpaper and aluminum parts lubricated with plenty of water. Depending on how many parts you are finishing, this can take anywhere from 20 minutes to 1 hour.

- Do not use circular motions, as this leaves swirling patterns on the metal. Instead, rub the paper back and forth, all in a specific direction.

Step 4

- Rinse the metal parts well and get a bowl of fresh water. Pour a few dabs of car soap on the 400 grit sandpaper and wet it thoroughly.

- Repeat the rubbing process, but this time work the paper in a back and forth direction perpendicular to the first.

Step 5

- Continue to rinse and rub the pieces, gradually working your way up to 2,000 grit sandpaper.

- At this point, the surface of the pieces should be smooth as glass and not have any of the glossy factory finishes that they started with.

Step 6

- Use cleaner towels to completely dry every inch of the aluminum parts. Leave them in the sun to dry if necessary.

- Adjust your mini polisher on your variable speed drill and saturate the head with polished aluminum. Wash the metal parts as well as the sanding.

Step 7

- Allow the polish to set for a few minutes before using your polishing cloths to polish the surfaces. At this point, your aluminum should be a dead ring for chrome.

Step 8

- Keep up all your hard work with a high quality aluminum sealant, as unfinished aluminum has a tendency to develop flaky corrosion. Yes, this means more polishing.

Step 9

- Reface the parts back on your bike, once the sealant has dried.

Aluminum Polishing Discs

- Special soft polishing discs that will produce a high gloss and mirror finish faster. Ideal for mirror finishing jobs.

- Non-woven flap discs are mainly used for cleaning, sanding and polishing (stainless steel), aluminum, copper, bronze, nickel, plastic, zinc, ceramic and non-ferrous materials.

- Non-woven flap discs are manufactured from open, reinforced nylon fibers.

Aluminum Polishing Products

- There are kits that contain the products needed to polish aluminum, these are the specifications of most of these kits.

- Two 10″ orange/yellow polishing wheels

- Two 10″ cotton polishing wheels, white / blue, untreated, soft cotton for a better high gloss finish

- A safety flange kit of coated steel for added protection.

- A Menzerna green blush bar for unmatched heavy cutting power and fast sanding mark removal 220

- A Menzerna blue blush bar for maximum brightness and clarity

- A polishing wheel cleaning rake for a smoother finish.

Learn How to Do Things in ALPHAPEDIA

HOW TO PAINT PINE WOOD ?

¿ HOW TO CLEAN GRANITE FLOORS ?

HOW TO UPHOLSTER A CHAIR ?

HOW TO INSTALL PARQUET FLOORING ?

HOW TO SMOOTH WALLS Step by Step ?

HOW TO REMOVE MOLD FROM CLOTHES ?

Information for the Development of Projects in ALPHAPEDIA

💚 WHEN ELECTRICITY WAS INVENTED ?

HOW TO POLISH MARBLE ?

HOW TO MAKE A WOODEN PLANTER ?

INDOOR SOCCER FIELD DIMENSIONS

CARTOON FIREPLACE Decorated and For Christmas: How to Make Them ?

WHAT DOES ELECTRICITY MEAN ?

Other Topics of Interest in ALPHAPEDIA

AQUARIUS: Meaning, Characteristics and Personality

FREE BACHELOR DEGREE IN CHILD, YOUTH AND FAMILY

FREE MOBILE REPAIR COURSE

HOW TO CARE FOR AND MAINTAIN THE WOOD OUTSIDE ?

FREE TELECOMMUNICATIONS COURSE

FREE MASTER DEGREE IN OCCUPATIONAL MEDICINE

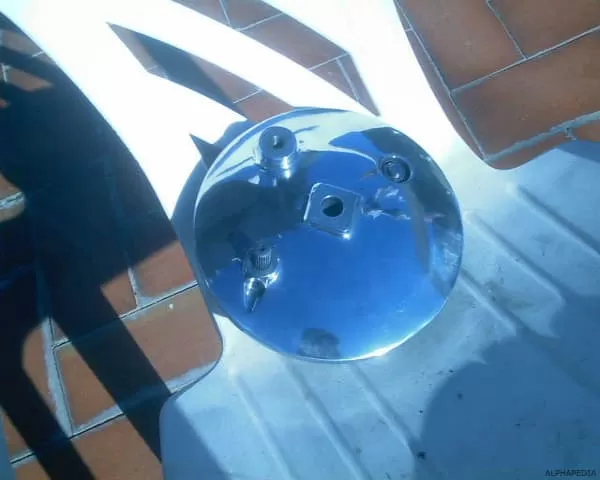

How to Polish Aluminium Image