What is a Woodworking Mandrel ?

It is a bar, axis or spindle around which other components are arranged or assembled. The mandrel is a mechanical device that allows you to hold any circular or square shaped piece with a specific diameter. This tool allows you to perform a specific job with precision. The most common machines equipped with a spindle are the Lathe and the Drill. With time, the spindle loses its effectiveness and it is advisable to change it.

Mandrel for Wooden Lathe in Spain

It is a precisely machined steel bar, kept on the lathe to ensure precise rotation of the boom when a live centre is used. No drill mandrel is required; the mandrel is held directly in the Morse taper of your lathe. The mandrel simplifies turning the project disc to exactly the right diameter. The mandrel are designed to fit on a lathe using a mounted drill mandrel with a 3/8″ capacity.

Drill Mandrel in United State and Canada

A drill mounting mandrel is attached to the drill in the same way as the drill bits are inserted. Once the mandrel is securely attached to the drill, simply insert the mandrel into the hole in the wheel shaft or cutting blade.

This allows for safe mounting of 2 to 3″ diameter cutting blades on most electric and pneumatic grinders and drills. It is designed to fit small diameter cutting wheels with a 3/8″ mandrel hole. These reinforced small diameter cutting blades allow for fast cutting and grooving on all types of metals.

The Bench Saw Mandrel

The bench saw is a box or base in which there is a mandrel or shaft that, at one end, carries the saw blade, and at the other, the pulley with which it is connected to the engine. The saw blades rise or fall by turning a handle and can be fixed firmly at any desired height. The cover of the bench is the work table. It has a slot in the middle, through which the saw blade comes out.

The saw has a scale that shows the tilt angle of the blade. With another handle it is possible to make the blade tilt at any angle, up to 45 degrees, to make perfect bevel cuts.

Spinning Mill Mandrel

In a carpenter’s spinning top, the tool’s mandrel is designed for mounting knives or cutters, the mandrel is on a cross slide that is driven by a handwheel, to accurately calibrate the cutting height. Ideal for general workshops and home use.

Mandrel for Woodworking Saws

There are various sizes and designs of woodworking saws on the market, more or less mechanized, that is, equipped with mechanisms that allow you to tilt the shaft, the cover or make the shaft go down or up to adjust the angle or height of cut. But the basic principle of every circular saw (no matter the size) is always a mandrel, whose main parts are

A steel shaft, turned and threaded at one end and externally turned at the other to mount a stepped pulley and at the same end a Morse taper No. 2 which serves to have the possibility of drilling on the same machine, selecting the appropriate speed.

- Hexagonal nut, to hold the plates.

- Metal plates to fix the toothed disc to the shaft.

- Toothed disc, whose diameter depends on the power of the motor and the capacity of the machine.

- Ball bearings (ball bearings).

- Mandrel body.

- Step pulley in “V” or flat (according to safety standards).

- Drill mandrel (optional) to give the machine the possibility to drill.

How to Change a Drill Chuck

First, it is advisable to start by closing the drill with a vise. The drill should be turned with the tip towards the other. Assemble the extractor and turn the lever until it is as close as possible to the base of the chuck. As the chuck is squeezed, it disengages from the cone. Now install the new spindle. In this case, we will need a hammer to carry out the threading function until complete adherence.

How to Make a Home Mandrel ?

To make the chuck we can use a piece of M8 metric threaded rod, and place two stainless screws at the end so they are ready to weld together.

- After welding the screws together, they are forged with a hammer to harden it.

- Then the chuck is carved to size. To bring it to the correct size and shape, the end of the threaded rod is placed in a drill and then sanded in a disk sander,

- Then we check the manrel setting and it’s ready to use.

How to Change a Dewalt Drill Mandrel ?

To Change a Dewalt Drill Chuck:

- Remove the inner clamping screw with a T15 Torx screwdriver

- The screw on the drill chuck has a reverse thread, which means that you will have to unscrew it counter-clockwise.

- Insert the Allen key into the drill chuck and turn it clockwise to tighten the key.

- Tap the Allen key with a hammer or chuck to loosen and remove the chuck.

- Tap the Allen key from above. The chuck loosens clockwise.

- Remove the chuck from the drill.

- Check the drill chuck assembly for damage or debris.

- If replacing the chuck, attach a new chuck and check the functionality.

- If debris is removed from a jam, make sure the drill chuck assembly is clear before reattaching it and checking functionality.

How to Change a Makita Drill Mandrel ?

Replacing a Makita drill chuck is the same as replacing most other brands of drill chucks.

- The key is to get the drill chuck loose from the shaft after removing a screw that holds the drill chuck.

- Buy a matching chuck for a good fit on your Makita drill.

Things you will need:

- Phillips head screwdriver

- 1/4 inch Allen wrench (larger if not 1/4 inch)

- Hammer

- Spare chuck

Press the locking tab on each side of the battery and remove the battery from the Makita drill. Turn the drill holder counterclockwise to open the jaws of the drill. Look into the center of the chuck and locate the screw that secures the chuck to the shaft.

Remove the security screw from the chuck with a Phillips screwdriver. You must turn the screw clockwise because the screw is a left-handed thread. Insert the short end of a 1/4 inch or larger Allen wrench into the drill holder and tighten it around the wrench as you would a drill. Tighten the drill chuck around the Allen wrench with the drill chuck key.

Place the Makita drill sideways, with the long end of the Allen wrench pointing to the left. Tap the Allen key with a hammer to turn the drill chuck counterclockwise. Remove the chuck from the shaft by hand. Screw the new chuck onto the shaft and open the jaws completely. Secure the chuck to the spindle with the retaining screw. Turn the screw counterclockwise to tighten. The drill chuck will seat itself the first time you use the drill.

How to Change the Mandrel of a Bench Drill ?

To replace or reinstall your chuck in the boom shaft, lift the boom to the highest position and tighten the boom lock to secure the shaft. Turn the drill press table so that it does not interfere with the installation of the chuck.

Then slide the tapered shank into the quill shaft. Turn the chuck slightly by hand until the square head on top of the shank fits into the receptacle inside the quill shaft. Fully retract the jaws and tap the bottom of the drill chuck once firmly with a mallet to seat the drill chuck stem in the quill shaft.

Rotate the chuck collar to check the operation of the chuck, then turn on the motor and insert a drill bit into the chuck to make a couple of test holes to make sure the reinstalled chuck is working properly.

How to Disassemble a Woodworking Mandrel

The first thing to do to disassemble the woodworking chuck is to pull down the handle to lower the boom and chuck to the stop, and turn the boom lock to keep the mechanism in the lowered position. Then look for a large vertical slot within the boom shaft. Some drill presses are equipped with such a slot, in which a drill chuck removal key can be inserted.

A tap on the end of the extraction key with a mallet will pull the chuck out of the boom spindle. If your drill chuck does not have an extraction key and corresponding slot, lift the quill until the top edge of the drill chuck collar is approximately 1/2-inch below the drill housing, and tighten the quill lock to secure the quill.

- Then slide the mouth of a large open-end wrench over the quill shaft just above the collet of the drill chuck.

- Push the large wrench up firmly to remove the chuck from the boom shaft.

Reference Price in Euros for a Woodworking Mandrel

- Three-jawed chuck, clamping diameter 1.8~56mm/12~65mm, Z011 for mini lathe Price: EUR 32.00.

- 3-Jaw Self-Centering Mill Chuck with 125mm Diameter – K11 Series – 105212 Price: EUR 79.10.

- 3-Jaw Self-Centering Lathe Milling Chuck with 80mm Diameter – K11 Series Price: EUR 47.71

Related Products in ALPHAPEDIA

WHAT IS A TAPE MEASURE: Types and Brands

ACCESSORIES FOR Orbital and Drill SANDING MACHINES

ANGLE GRINDER: Types, Prices ans Brands as Makita and Bosch

MILLING MACHINE: Types, Brands and Prices

MANUAL HAND SANDER: Brands as Dewalt and Black & Decker

💚 WALL SANDER: ¿ How to Use It ? Brands and Models

Other Topics of Interest in ALPHAPEDIA

FREE DOCTORATE IN CRIMINAL LAW

FREE ASSISTING IN HOME CARE COURSE

FREE BACHELOR DEGREE IN BROMATOLOGY

FREE EMERGENCY MEDICINE COURSE

FREE MASTER DEGREE IN ORTHODONTICS

💚 VOLLEYBALL COURT DIMENSIONS

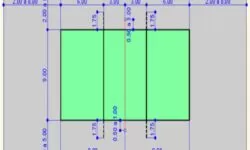

Mandrel Image